Besides local manufacturing, the decentralizing manufacturing is necessary for future of manufacturing to enable higher productivity and increase capabilities for addressing international market demand change. We can provide one-stop manufacturing services in Vietnam.

Vietnam has become an increasingly popular country for electronics manufacturing because of its strategic location, lower labor costs, and favorable policies for manufacturing and international trading.

Our Vietnam partner was established in 2019, it is a high-tech electronic products enterprise (EPE), and offers OEM services for global clients. It is a modern factory with14,000 square meters, 13 SMT lines and 500 workers in Vietnam.

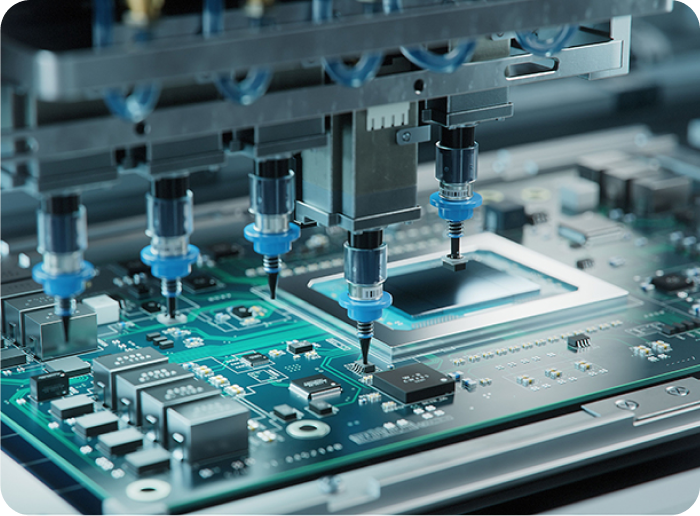

PCB Assembly Capability

Our advanced SMT & PCB Assembly technology with validated processes and a full range of services from NPI to mass production.

We also have equipment

for reflow, coating machines.

Equipment

smart device revolution is shaping every stage of manufacturing

more

cost efficient and sustainable

Full-automatic printing machine

Suitable for any material, compatible with a wide range of surfaces

Selective Wave Soldering

selective welding heads for different sizes and shapes High soldering precision and effectiveness

Digital Depaneling

Automatic depaneling

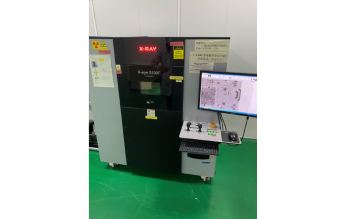

Testing and Inspection

We use state-of-the-art automated inspection systems like Solder Paste

Inspection(SPI), AOI, X-Ray, In-Circuit Testing,

Functional Test and First Article Inspection

(FAI) to ensure the highest quality possible.

Solder Paste Inspection Machine

Detect soldering defect Improve yield rate

X-Ray

for BGA analysis

Automatic Optical Inspection

Detect defect before assembly

Mechanical Assembly

With widely available resources, we can supply various mechanical parts containing injection molding, CNC, casing and 3D printing etc We help to complete your subassemblies and final assemblies smoothly and efficiently thanks to our developed and standardize assembly processes.

Engineering

Free Design for X services ensure the smooth transition from design to the factory, covering Design for Manufacturability (DFM), Design for Test (DFT), Design for Quality(DFQ), Design for Assembly (DFA) as well as PCB EQ and FMEA.

Quality and Reliability

Semitown’s Quality Management System (QMS) is certified ISO9001 by TUV. We regularly check our systems and records to confirm that our products, processes and documentation are in line with the guidelines and customers’ requirements. We support reliability test including drop test, vibration test, thermal shock and temperature cycling etc. Meanwhile, we can perform compliance test and serve extensive product safety certifications by UL, TUV, SGS according to customer’s market demand. Semitown can provide COO certificate for all products manufactured in Vietnam factory.

Temperature Cycling

Thermal Shock

vibration test